Optoboard System

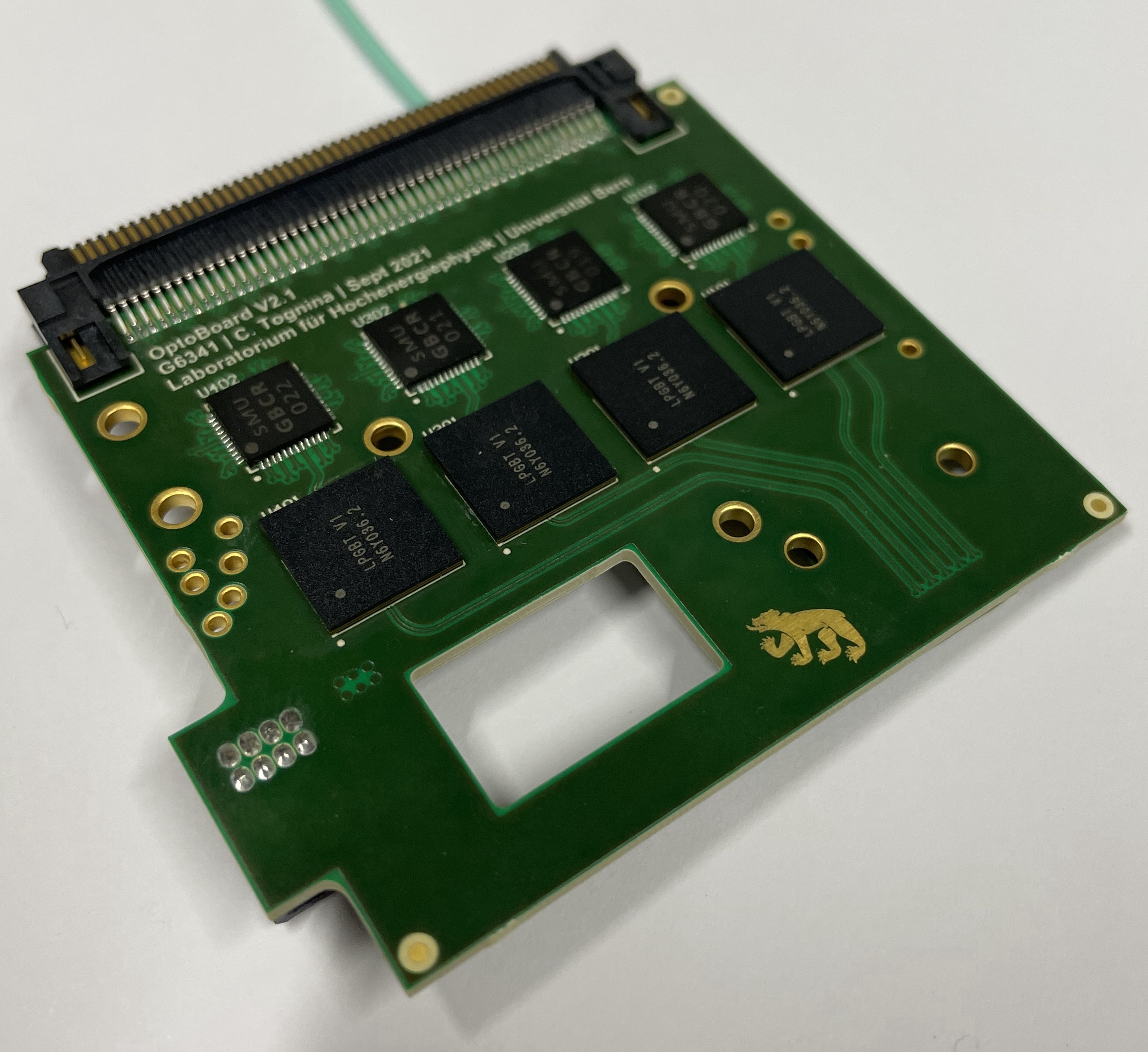

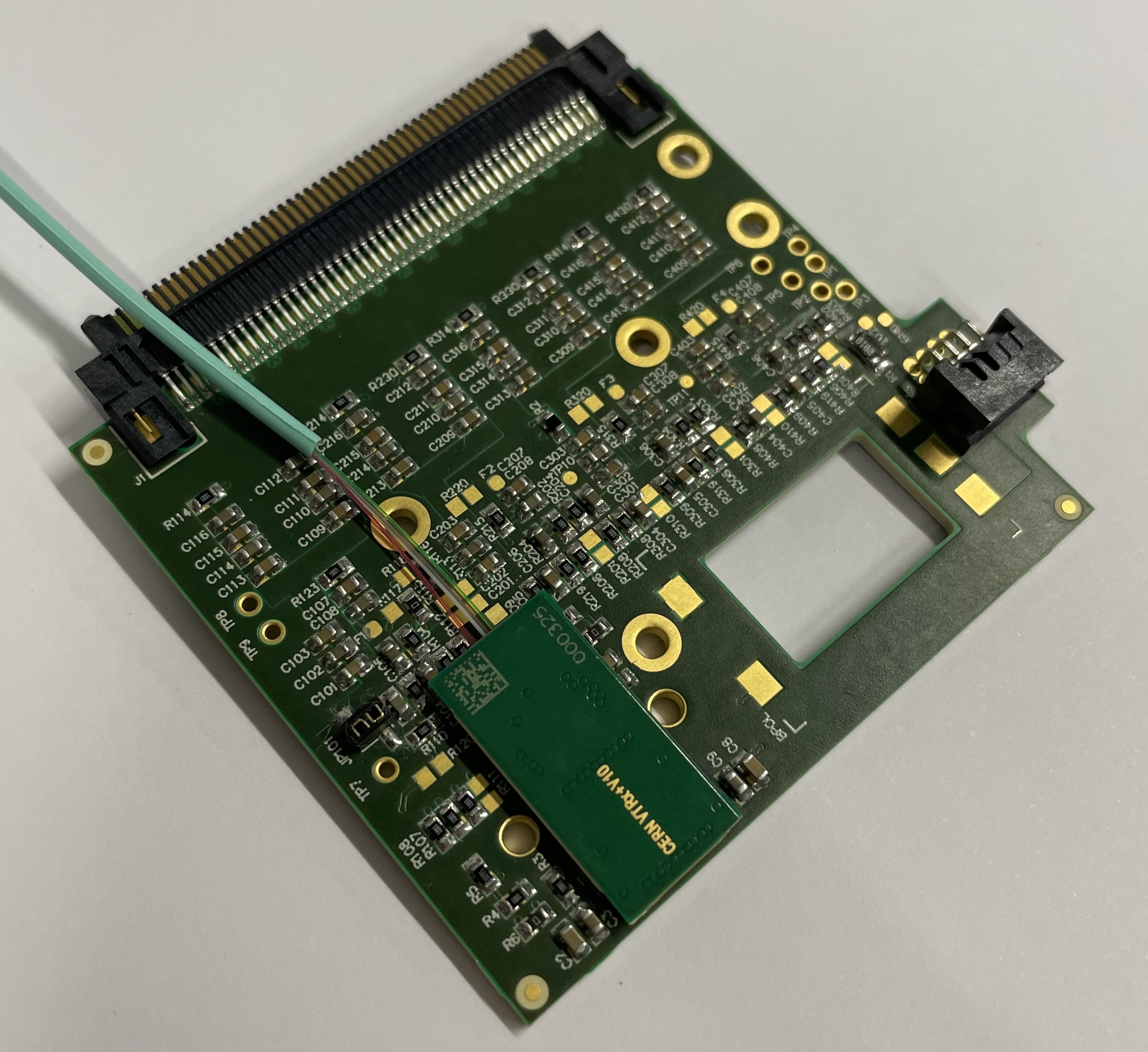

The Optoboard System is the optical-electrical conversion system dedicated to the readout of the ATLAS [1] Inner Tracker (ITk) Pixel detector [2] intended for the High Luminosity LHC (HL-LHC) [3, 4] era. This pivotal component of the ITk Pixel detector data transmission chain contains at its heart a PCB, the Optoboard, that hosts a series of ASICs intended to aggregate electrical data links and subsequently convert them to optical signals for transmission to the ATLAS counting rooms via fibre optical cables.

The second function operates in the reverse sense where optical signals are converted to electrical links and disseminated to the modules providing clock and command signals.

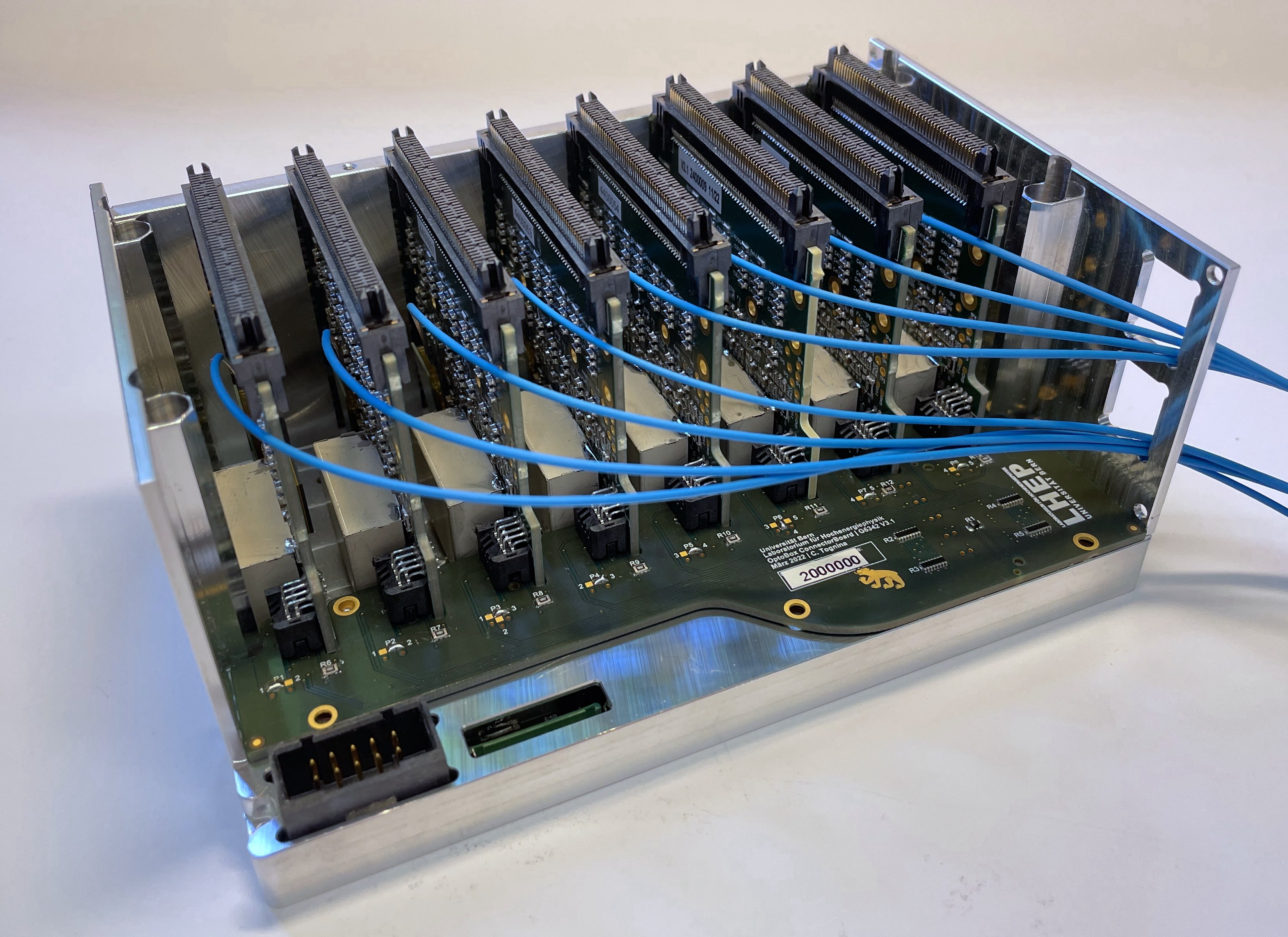

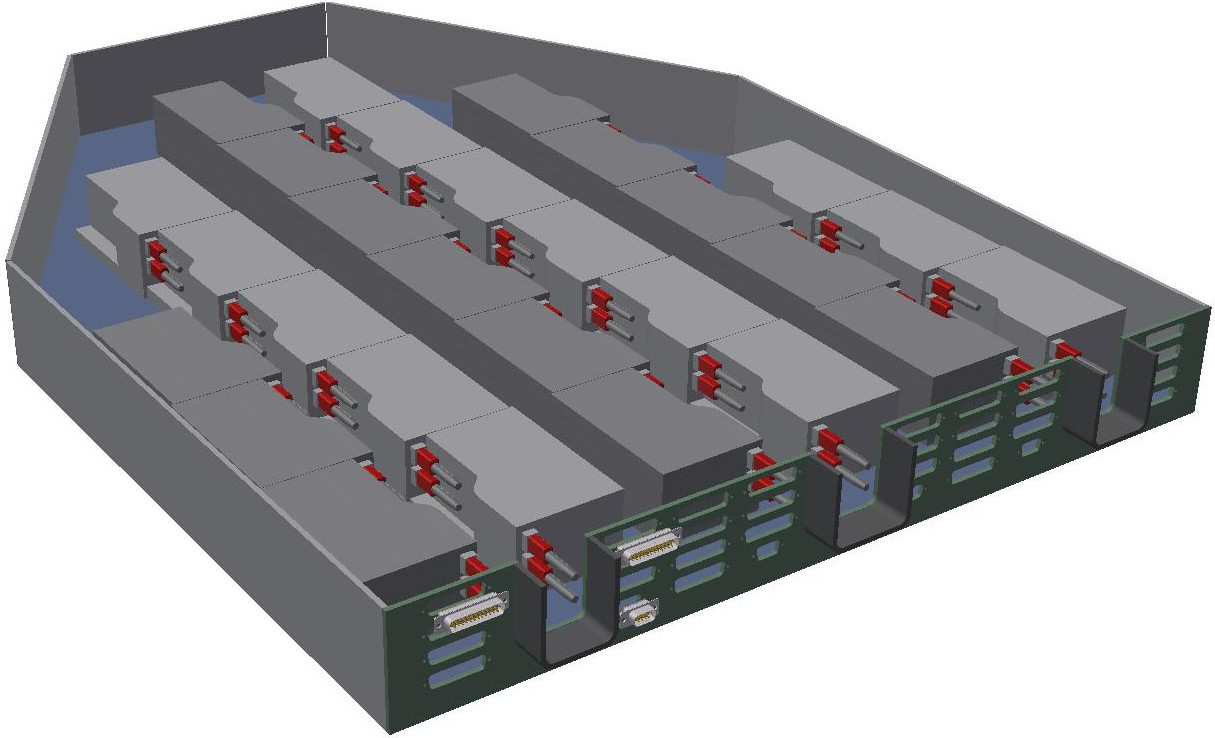

The Optoboards are hosted in a mechanical structure known as an Optobox, up to eight Optoboards may reside inside an Optobox. The number of Optoboards depends on the number of data links coming from a particular sub-detector of the ITk Pixel detector.

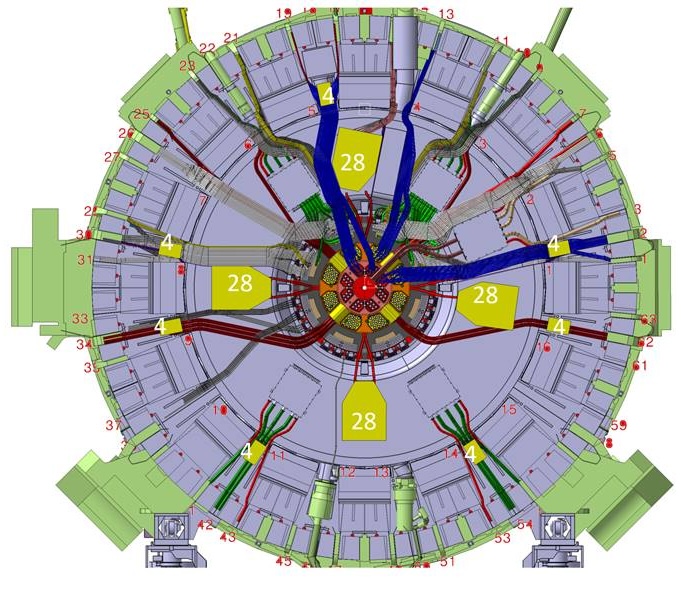

The Optoboxes are then housed in a mechanical structure known as Optopanel. Inside an Optopanel there are 28 Optoboxes and there are four Optopanels at each end of the ATLAS ITk Pixel detector.

My involvement

I actively developed the design, testing and commissioning of the Optoboard and the powering- and monitoring distribution system, including mechanical services, up until pre-production. This includes a detailed characterisation of radiation-hard buck point-of-load power converters and possible cooling strategies. I have gained fundamental knowledge of operation, calibration and tuning of silicon pixel detectors for the commissioning and validation of the Optoboard System. Furthermore, I built a documentation website and created a highly active support channel with more than 50 users for the distributed Optoboards at various international detector test sites for streamlined, efficient collaboration.

The aggregation in the ITk Pixel Detector data transmission chain is performed by the low-power Gigabit Transceiver (lpGBT) chip, controllable through a two wire bus (I2C) or optical link. I designed and developed the Python control and testing software (including a GUI) optoboard felix to enable users to carry out fast configuration for hundreds of registers and perform testing routines, such as jitter and bit error rate tests, for commissioning of data transmission chains.